| Model | Voltage | Actual capacity | N.W. | L*W*H*Total hight |

| DKOPzV-200 | 2v | 200ah | 18.2kg | 103*206*354*386 mm |

| DKOPzV-250 | 2v | 250ah | 21.5kg | 124*206*354*386 mm |

| DKOPzV-300 | 2v | 300ah | 26kg | 145*206*354*386 mm |

| DKOPzV-350 | 2v | 350ah | 27.5kg | 124*206*470*502 mm |

| DKOPzV-420 | 2v | 420ah | 32.5kg | 145*206*470*502 mm |

| DKOPzV-490 | 2v | 490ah | 36.7kg | 166*206*470*502 mm |

| DKOPzV-600 | 2v | 600ah | 46.5kg | 145*206*645*677 mm |

| DKOPzV-800 | 2v | 800ah | 62kg | 191*210*645*677 mm |

| DKOPzV-1000 | 2v | 1000ah | 77kg | 233*210*645*677 mm |

| DKOPzV-1200 | 2v | 1200ah | 91kg | 275*210*645*677mm |

| DKOPzV-1500 | 2v | 1500ah | 111kg | 340*210*645*677mm |

| DKOPzV-1500B | 2v | 1500ah | 111kg | 275*210*795*827mm |

| DKOPzV-2000 | 2v | 2000ah | 154.5kg | 399*214*772*804mm |

| DKOPzV-2500 | 2v | 2500ah | 187kg | 487*212*772*804mm |

| DKOPzV-3000 | 2v | 3000ah | 222kg | 576*212*772*804mm |

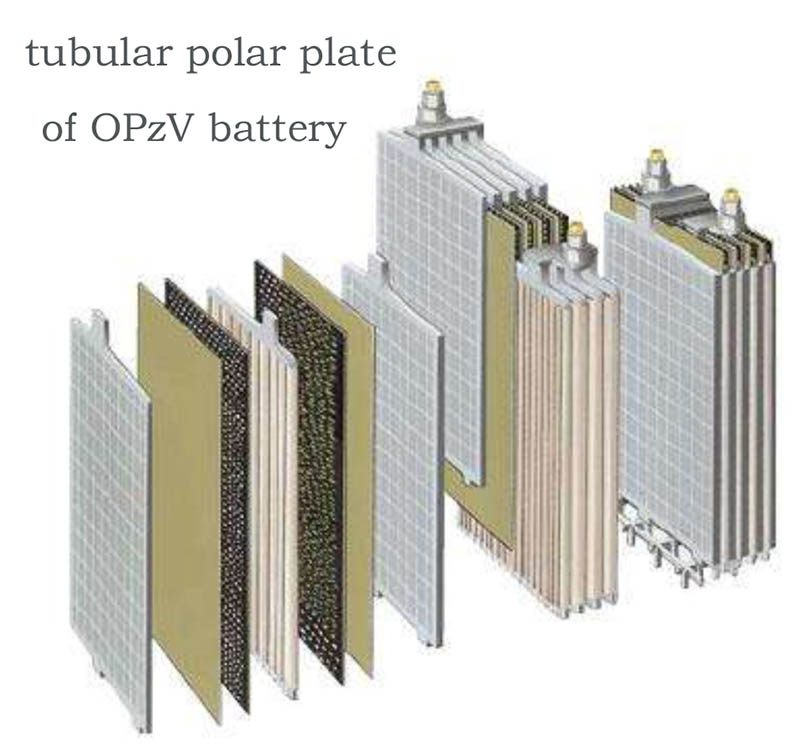

D King OPzV battery, also named GFMJ battery The positive plate adopts tubular polar plate, so it also named tubular battery. The nominal voltage is 2V, the standard capacity normally 200ah, 250ah, 300ah, 350ah, 420ah, 490ah, 600ah, 800ah, 1000ah, 1200ah, 1500ah, 2000ah, 2500ah, 3000ah. Also customized capacity are produced for different applications.Structural characteristics of D King OPzV battery: 1. Electrolyte: Made of German fumed silica, the electrolyte in the finished battery is in gel state and does not flow, so there is no leakage and electrolyte stratification. 2. Polar plate: The positive plate adopts tubular polar plate, which can effectively prevent the falling off of living substances. The positive plate skeleton is formed by multi alloy die casting, with good corrosion resistance and long service life. The negative plate is a paste type plate with a special grid structure design, which improves the utilization rate of living materials and the large current discharge capacity, and has strong charging acceptance capacity.

D King OPzV battery, also named GFMJ battery The positive plate adopts tubular polar plate, so it also named tubular battery. The nominal voltage is 2V, the standard capacity normally 200ah, 250ah, 300ah, 350ah, 420ah, 490ah, 600ah, 800ah, 1000ah, 1200ah, 1500ah, 2000ah, 2500ah, 3000ah. Also customized capacity are produced for different applications.Structural characteristics of D King OPzV battery: 1. Electrolyte: Made of German fumed silica, the electrolyte in the finished battery is in gel state and does not flow, so there is no leakage and electrolyte stratification. 2. Polar plate: The positive plate adopts tubular polar plate, which can effectively prevent the falling off of living substances. The positive plate skeleton is formed by multi alloy die casting, with good corrosion resistance and long service life. The negative plate is a paste type plate with a special grid structure design, which improves the utilization rate of living materials and the large current discharge capacity, and has strong charging acceptance capacity. 3. Battery shell Made of ABS material, corrosion resistant, high strength, beautiful appearance, high sealing reliability with the cover, no potential leakage risk. 4. Safety valve With special safety valve structure and proper opening and closing valve pressure, water loss can be reduced, and expansion, cracking and electrolyte drying of battery shell can be avoided. 5. Diaphragm The special microporous PVC-SiO2 diaphragm imported from Europe is used, with large porosity and low resistance. 6. Terminal Embedded copper core lead base pole has greater current carrying capacity and corrosion resistance. Key advantages compare to normal gel battery: 1. Long life time, floating charge design life of 20 years, stable capacity and low decay rate during normal floating charge use. 2. Better cycle performance and deep discharge recovery. 3. It is more capable of working at high temperature and can work normally at - 20 ℃ - 50 ℃.

3. Battery shell Made of ABS material, corrosion resistant, high strength, beautiful appearance, high sealing reliability with the cover, no potential leakage risk. 4. Safety valve With special safety valve structure and proper opening and closing valve pressure, water loss can be reduced, and expansion, cracking and electrolyte drying of battery shell can be avoided. 5. Diaphragm The special microporous PVC-SiO2 diaphragm imported from Europe is used, with large porosity and low resistance. 6. Terminal Embedded copper core lead base pole has greater current carrying capacity and corrosion resistance. Key advantages compare to normal gel battery: 1. Long life time, floating charge design life of 20 years, stable capacity and low decay rate during normal floating charge use. 2. Better cycle performance and deep discharge recovery. 3. It is more capable of working at high temperature and can work normally at - 20 ℃ - 50 ℃.

Lead ingot raw materials

Polar plate process

Electrode welding

Assemble process

Sealing process

Filling process

Charging process

Storage and shipping

Safety characteristics (1) Battery shell: OPzV solid lead battery is made of flame-retardant ABS material, which does not burn; (2) Partition: PVC-SiO2/PE-SiO2 or phenolic resin partition is used to inhibit internal combustion; (3) Electrolyte: The electrolyte adopts nano-vapor silica; (4) Terminal: tinned red copper core, low resistance, sealed pole technology to avoid battery pole leakage. (5) Electrode plate: the positive grid is made of lead calcium tin alloy, which is die-cast under the pressure of 10 MPa. Charging characteristics (1) During floating charging, constant voltage 2.25V/cell (set value at 20 ℃) or current below 0.002C shall be used for continuous charging. When the temperature is below 5 ℃ or above 35 ℃, the temperature compensation coefficient is - 3mV/cell/℃ (based on 20 ℃). (2) During equalizing charging, constant voltage 2.30-2.35V/cell (set value at 20 ℃) is used for charging. When the temperature is below 5 ℃ or above 35 ℃, the temperature compensation coefficient is - 4 mV/cell/℃ (based on 20 ℃). (3) The maximum initial charging current is 0.5C, the intermediate charging current is 0.15C, and the final charging current is 0.05C. The best charging current is 0.25C. (4) The charging capacity should be set at 100%~105% of the discharge capacity, but when the ambient temperature is below 5 ℃, it should be set at 105%~110%. (5) The lower the temperature (below 5 ℃), the longer the charging time. (6) Intelligent charging mode is adopted to effectively control charging voltage, charging current and charging time. Discharge characteristic (1) The temperature range during discharge shall be between - 45 ℃ and+65 ℃. (2) The continuous discharge rate or current is applicable for 10 minutes to 120 hours, and there is no fire or explosion in short circuit. (3) The discharge termination voltage varies according to the discharge current or rate: Battery life OPzV solid lead battery is widely used in new energy systems such as medium and large energy storage, power, communication, petrochemical, rail transit, solar energy and wind energy. Process characteristics (1) The grid made of lead-calcium-tin special alloy die-casting can inhibit the grid corrosion expansion, prevent internal short circuit, increase hydrogen evolution overvoltage, inhibit hydrogen generation and prevent electrolyte loss. (2) The technology of one-time gelatinizing and internalization is adopted, and the solid electrolyte formed at one time has no free liquid. (3) The battery adopts a valve seat safety valve with opening and reclosing functions, which can automatically adjust the internal pressure of the battery; Keep the battery airtight and prevent external air from entering the battery. (4) The plate adopts high temperature and high humidity curing process to control the structure and content of 4BS in the active material, and ensure the battery life, capacity and batch consistency. Energy consumption characteristics (1) The self-heating temperature of the battery shall not exceed 5 ℃ of the ambient temperature to minimize its own heat loss. (2) The internal resistance of the battery is low, and the energy consumption of the battery energy storage system with a capacity of more than 2000Ah is less than 10%. (3) The battery self-discharge is small, and the monthly self-discharge capacity loss is less than 1%. (4) The battery is connected with large-diameter flexible copper wire, with low contact resistance and low line loss. Environmental characteristics (1) It is recommended to store at the ambient temperature of - 20 ℃~+50 ℃. (2) The battery must be fully charged during storage. Because some capacity will be lost due to self-discharge during transportation or storage period, please recharge before use. (3) For long-term storage, please recharge regularly (it is recommended to recharge every six months). (4) Please store in a dry and ventilated place at low temperature. Advantages (1) Large temperature resistance range, - 45 ℃~+65 ℃, can be widely used in various scenarios. (2) Applicable to medium and large rate discharge: meet the application scenarios of one charge and one discharge and two charge and two discharge. (3) It has a wide range of application scenarios and is suitable for medium and large energy storage. It is widely used in industrial and commercial energy storage, power generation side energy storage, grid side energy storage, data center (IDC energy storage), nuclear power station, airport, subway and other fields with high safety requirements.

Safety characteristics (1) Battery shell: OPzV solid lead battery is made of flame-retardant ABS material, which does not burn; (2) Partition: PVC-SiO2/PE-SiO2 or phenolic resin partition is used to inhibit internal combustion; (3) Electrolyte: The electrolyte adopts nano-vapor silica; (4) Terminal: tinned red copper core, low resistance, sealed pole technology to avoid battery pole leakage. (5) Electrode plate: the positive grid is made of lead calcium tin alloy, which is die-cast under the pressure of 10 MPa. Charging characteristics (1) During floating charging, constant voltage 2.25V/cell (set value at 20 ℃) or current below 0.002C shall be used for continuous charging. When the temperature is below 5 ℃ or above 35 ℃, the temperature compensation coefficient is - 3mV/cell/℃ (based on 20 ℃). (2) During equalizing charging, constant voltage 2.30-2.35V/cell (set value at 20 ℃) is used for charging. When the temperature is below 5 ℃ or above 35 ℃, the temperature compensation coefficient is - 4 mV/cell/℃ (based on 20 ℃). (3) The maximum initial charging current is 0.5C, the intermediate charging current is 0.15C, and the final charging current is 0.05C. The best charging current is 0.25C. (4) The charging capacity should be set at 100%~105% of the discharge capacity, but when the ambient temperature is below 5 ℃, it should be set at 105%~110%. (5) The lower the temperature (below 5 ℃), the longer the charging time. (6) Intelligent charging mode is adopted to effectively control charging voltage, charging current and charging time. Discharge characteristic (1) The temperature range during discharge shall be between - 45 ℃ and+65 ℃. (2) The continuous discharge rate or current is applicable for 10 minutes to 120 hours, and there is no fire or explosion in short circuit. (3) The discharge termination voltage varies according to the discharge current or rate: Battery life OPzV solid lead battery is widely used in new energy systems such as medium and large energy storage, power, communication, petrochemical, rail transit, solar energy and wind energy. Process characteristics (1) The grid made of lead-calcium-tin special alloy die-casting can inhibit the grid corrosion expansion, prevent internal short circuit, increase hydrogen evolution overvoltage, inhibit hydrogen generation and prevent electrolyte loss. (2) The technology of one-time gelatinizing and internalization is adopted, and the solid electrolyte formed at one time has no free liquid. (3) The battery adopts a valve seat safety valve with opening and reclosing functions, which can automatically adjust the internal pressure of the battery; Keep the battery airtight and prevent external air from entering the battery. (4) The plate adopts high temperature and high humidity curing process to control the structure and content of 4BS in the active material, and ensure the battery life, capacity and batch consistency. Energy consumption characteristics (1) The self-heating temperature of the battery shall not exceed 5 ℃ of the ambient temperature to minimize its own heat loss. (2) The internal resistance of the battery is low, and the energy consumption of the battery energy storage system with a capacity of more than 2000Ah is less than 10%. (3) The battery self-discharge is small, and the monthly self-discharge capacity loss is less than 1%. (4) The battery is connected with large-diameter flexible copper wire, with low contact resistance and low line loss. Environmental characteristics (1) It is recommended to store at the ambient temperature of - 20 ℃~+50 ℃. (2) The battery must be fully charged during storage. Because some capacity will be lost due to self-discharge during transportation or storage period, please recharge before use. (3) For long-term storage, please recharge regularly (it is recommended to recharge every six months). (4) Please store in a dry and ventilated place at low temperature. Advantages (1) Large temperature resistance range, - 45 ℃~+65 ℃, can be widely used in various scenarios. (2) Applicable to medium and large rate discharge: meet the application scenarios of one charge and one discharge and two charge and two discharge. (3) It has a wide range of application scenarios and is suitable for medium and large energy storage. It is widely used in industrial and commercial energy storage, power generation side energy storage, grid side energy storage, data center (IDC energy storage), nuclear power station, airport, subway and other fields with high safety requirements.